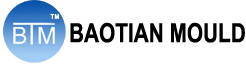

Introduction to common problems of plastic abrasive tools

It mainly includes a female mold with a variable cavity composed of a female mold combination substrate, a female mold component and a female mold combination card plate, and a male mold combination substrate, a male mold component, a male mold combination card, a cavity cutting component and A punch with a variable core composed of side-cut composite plates.

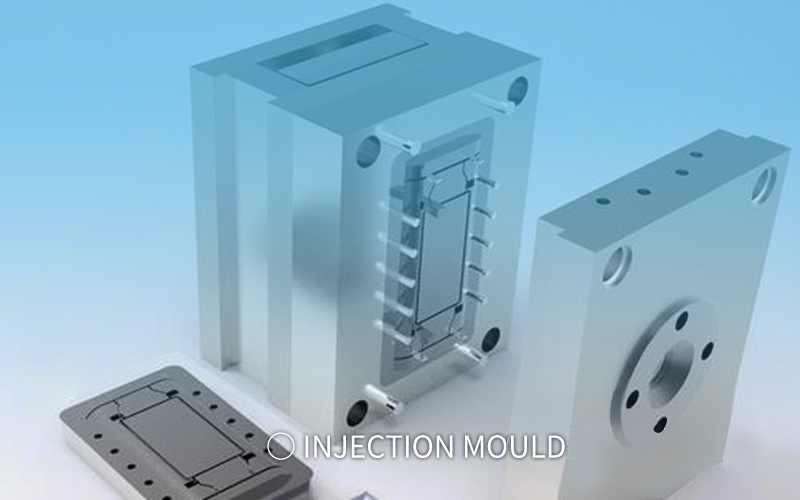

In order to improve the function of plastics, various auxiliary materials, such as fillers, plasticizers, lubricants, stabilizers, colorants, etc., must be added to the polymer to become a plastic with good functions.

1. Synthetic resin is the most important component of plastics, and its content in plastics is generally 40% to 100%. Because the content is large, and the nature of the resin often determines the nature of the plastic, people often regard the resin as a synonym for plastic. For example, confuse polyvinyl chloride resin with polyvinyl chloride plastics, and phenolic resins with phenolic plastics. In fact, resin and plastic are two different concepts. Resin is an unprocessed raw polymer. It is not only used to make plastics, but also as a material for coatings, adhesives, and synthetic fibers. In addition to a very small part of plastics that contain 100% resin, most plastics need to participate in other substances in addition to the primary component resin. 2. Filler Filler, also known as filler, can improve the strength and heat resistance of plastics, and reduce costs. For example, the participation of wood powder in the phenolic resin can greatly reduce the cost, making the phenolic plastic one of the cheap plastics, and at the same time it can significantly improve the mechanical strength. Fillers can be divided into two types: organic fillers and inorganic fillers, the former such as wood flour, rags, paper and various fabric fibers, and the latter such as glass fiber, diatomaceous earth, asbestos, carbon black and so on.

3. Plasticizers Plasticizers can increase the plasticity and flexibility of plastics, reduce brittleness, and make plastics easier to process and shape. Plasticizers are generally high-boiling organic compounds that are miscible with resin, non-toxic, odorless, stable to light and heat, and phthalate esters are commonly used. For example, when producing polyvinyl chloride plastics, if more plasticizers are used, soft polyvinyl chloride plastics can be obtained. If no or less plasticizers are added (amount <10%), hard polyvinyl chloride plastics can be obtained. .

4. In order to prevent the synthetic resin from being differentiated and damaged by light and heat during processing and use, and to prolong the service life, it is necessary to participate in the stabilizer in the plasticizer. Commonly used are stearate, epoxy resin and so on.

5. Colorants Colorants can make plastics have various beautiful and beautiful colors. Commonly used organic dyes and inorganic pigments as colorants.

6. Lubricant The role of lubricant is to prevent the plastic from sticking to the metal mold during molding, and at the same time, it can make the appearance of the plastic lubricious and beautiful. Commonly used lubricants include stearic acid and its calcium and magnesium salts. In addition to the above additives, Suchaizhong can also participate in flame retardants, foaming agents, antistatic agents, etc.

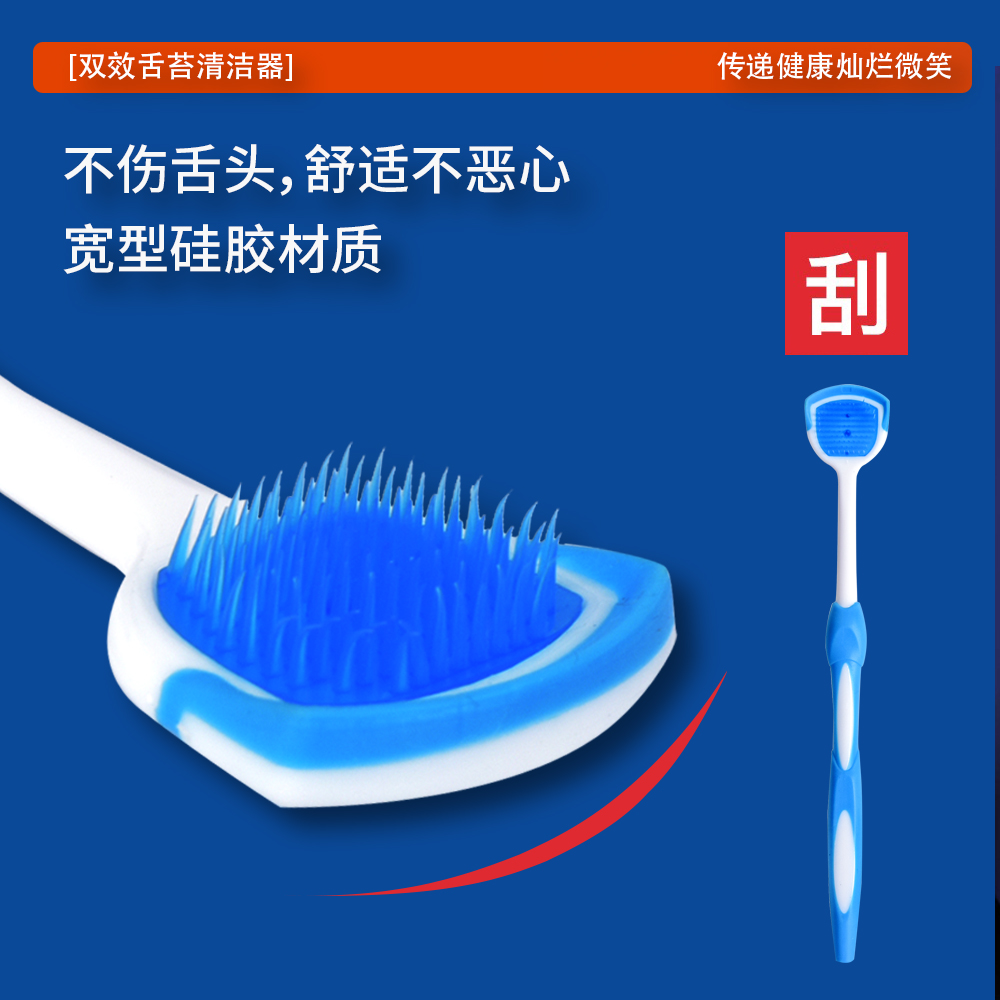

1. Don't just focus on product planning and ignore plastic mold manufacturing.

When some users develop products or trial production of new products, they often only focus on product R&D and development at the initial stage, neglecting communication with plastic mold manufacturers. After the product planning plan is confirmed, there are two advantages to early contact with mold manufacturers:

1. It can ensure that the planned product has a good forming process and will not modify the finalization plan due to the difficulty of processing the parts.

2. Only mold manufacturers can make planning preparations in advance to avoid ill-consideration in a hurry, which affects the construction period.

3. To manufacture high-quality plastic molds, only the supplier and the demander need to cooperate closely to reduce costs and shorten the cycle after all.

2. Don't just look at the price, but consider the quality, cycle, and service in all aspects.

1. There are many types of molds, which can be roughly divided into ten categories. According to different requirements of parts materials, physical and chemical functions, mechanical strength, dimensional accuracy, surface finish, service life, economic efficiency, etc., different types of mold forming are selected.

2. Molds with high precision requirements need to be processed by high-precision CNC machine tools, and mold materials and forming processes have strict requirements, and CAD / CAE / CAM mold skills are required to plan and analyze.

3. Because some parts have special requirements during molding, the mold needs to use advanced technology